How it’s made

The timber will be moved from the forest to the factory

After arriving by barge, logs are graded and then peeled

Veneers are dried under careful moisture control

The venners will be dried in the dryer duct to be dehydrate to avoid rotenning and warping of the plies

Veneers are jointed

Gluing and assembling before cold and hot pressing.

The gluing process is important to strengthen the bonds between each plies. This is to avoid warping of the plies.

After the hot press, boards are trimmed and graded into 1st grade, Baramagold, and 2nd grade, Baramaply.

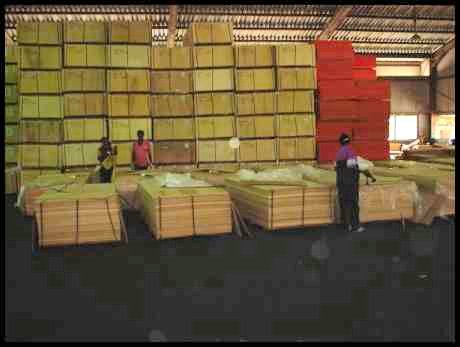

After the plywood are being checked and graded it is ready for shipment.

Boards are poly wrapped and packed into steel strapped plywood crates for export, either by container or direct from Barama’s factory wharf.

Comments (0)

Trackbacks (0)

Leave a comment

Trackback